Biomass and waste-fired boiler plants

Boiler plant solutions

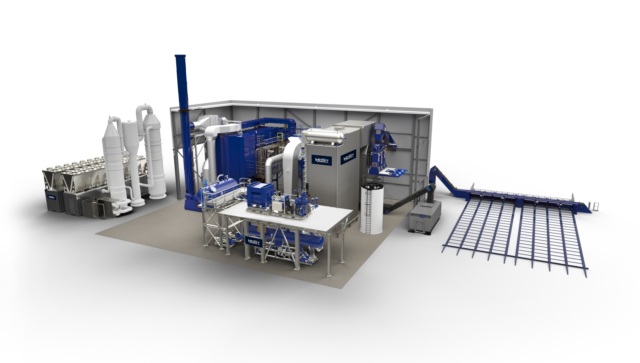

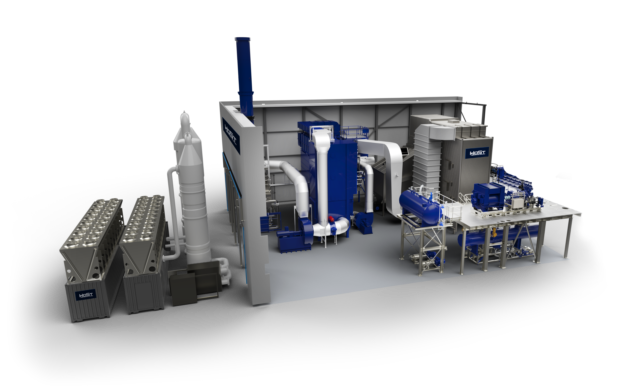

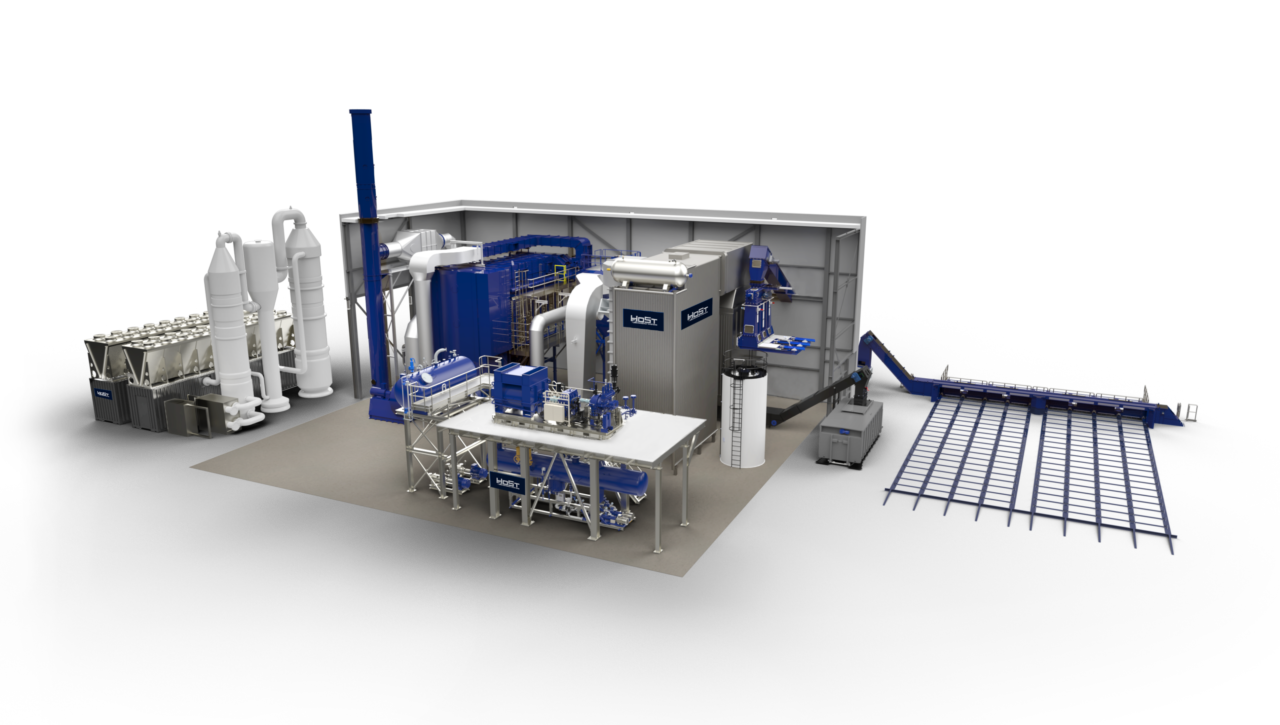

Our turnkey boiler plant solution

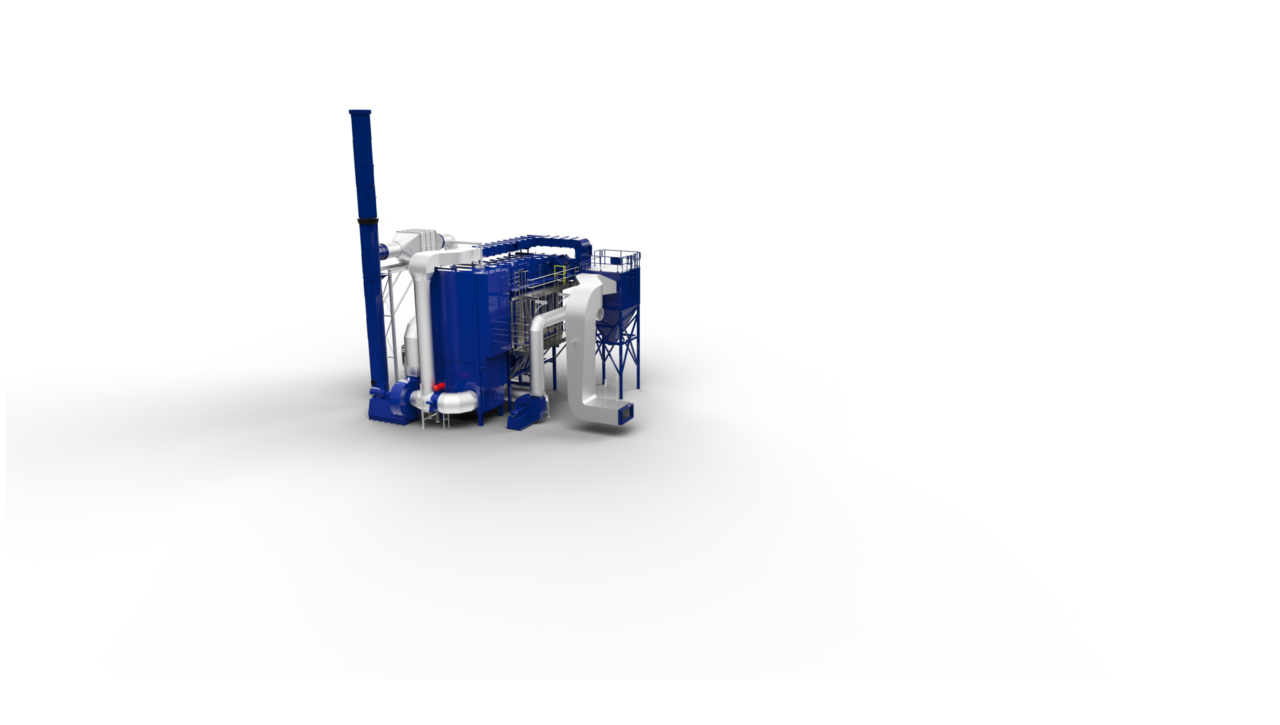

Our boiler plants are supplied with in-house technology. The below image is an illustrative representation of our turnkey boiler plant including carbon capture technology.

Features

- Standardized design

- Innovative technologies

- Highly automated

- Compact & modular build

- Low building height

- Carbon capture easily integratable

Clean heat & power

HoSt designs, constructs, installs, commissions, maintains, and operates WID/IED compliant industrial biomass and waste-fired boiler plants. For biomass, residual wood waste, agricultural waste products, or RDF, these residues can serve as fuel in our medium-sized boiler plants. Carbon capture technology can easily be integrated for capturing the CO2 from the flue gases and producing gaseous or liquid bio-CO2.

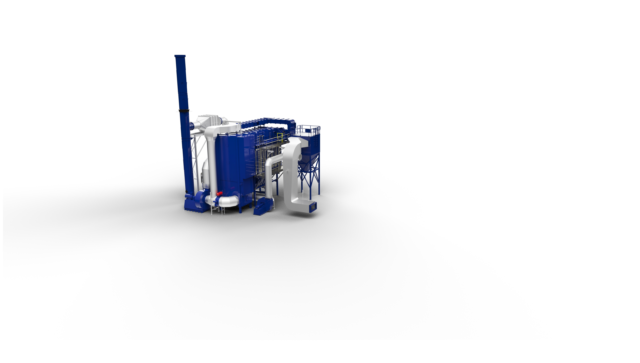

Boiler plant design

Driven by the strictest emission limits in the world, the highest quality standards and high automation demand our Dutch design boiler installations are the most innovative, robust, and cleanest boilers in the industry. With optimal combustion control and advanced automation, our systems reach increased efficiency, while achieving the lowest emissions in the industry. Our boiler plants reach over 96% availability with 8,400 yearly operational hours and have a versatile fuel compatibility.

Advantages

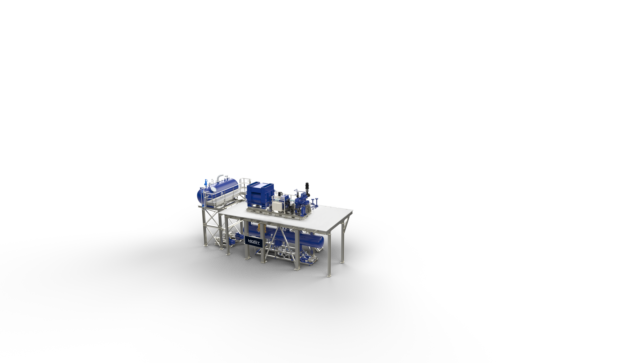

High electrical efficiency

By combining a high-pressure steam boiler with an efficient multistage steam turbine, over 25% electrical efficiency can be achieved. The strategic boiler placement reduces construction costs, while the plant’s design promises high performance and operational savings. High-pressure steam turns a turbine to generate electricity. The used steam then heats an external process via a steam condenser. A deaerator removes O2 and CO2 from the condensate, which feedwater pumps return to the boiler.

Industrial boilers for every industry

Our boiler systems serve a wide range of industries such as sawmills, pellet mills, cardboard and paper mills, greenhouses, district heating, process and chemical industries, and the food and beverage sector, among others. While engineered for any sector, these biomass and waste-fired boiler plants utilize the energy from biomass, wood waste and RDF, serving as a sustainable and high-energy source for generating renewable energy. Beyond generating renewable heat and electricity, our systems support industrial drying, process heat and steam, steam production, district heating thereby optimizing industrial operations and savings of fossil fuel energy and avoiding increase of CO2 in the athmosphere.

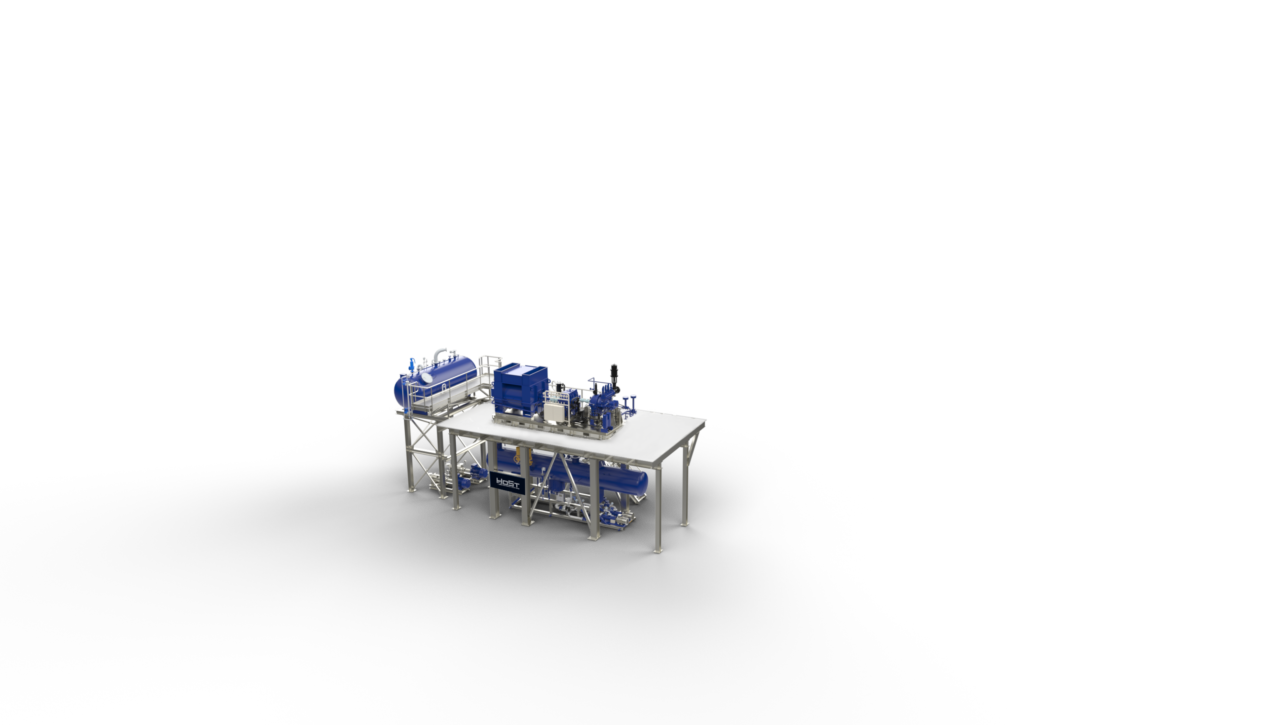

Biomass boiler plant Bemmel

Located in a thriving greenhouse region in the Netherlands, our biomass boiler plant eliminates the need for the traditional natural gas boiler. By turning area-sourced shredded wood waste into renewable heat and power, local growers meet their energy demands and reach their sustainability goals. Boosting its effectiveness, the plant reaches a high efficiency rate due to the integration of a flue gas condenser.

We realized boiler plants for